Description

FULLY AUTOMATIC BGA REWORK STATION

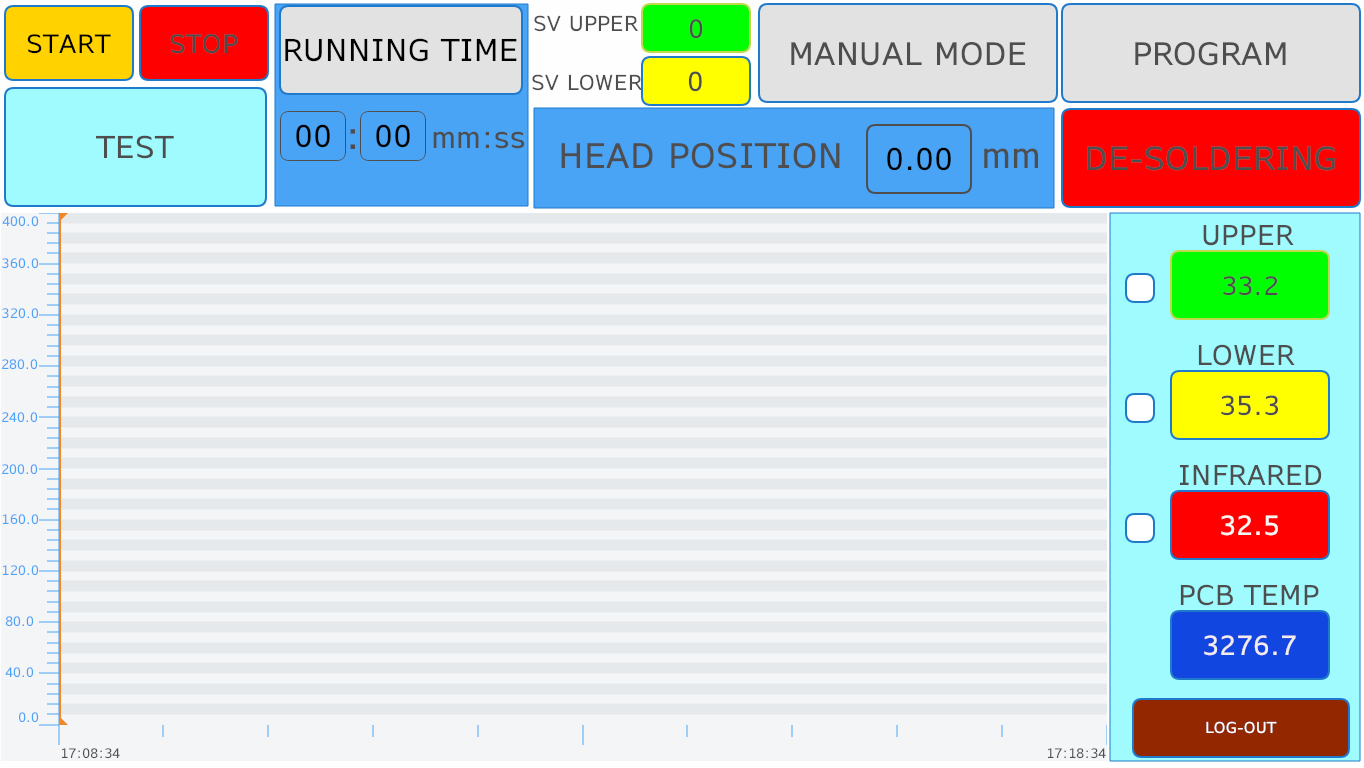

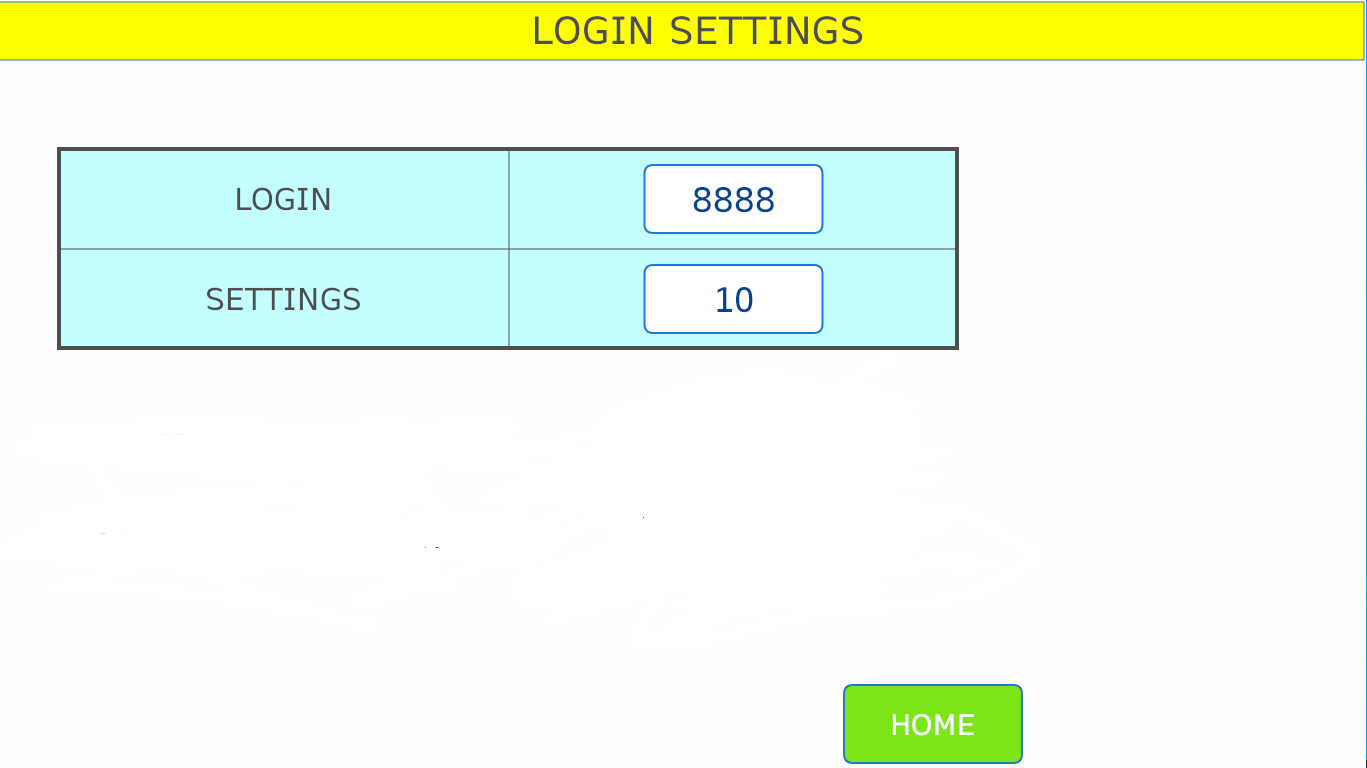

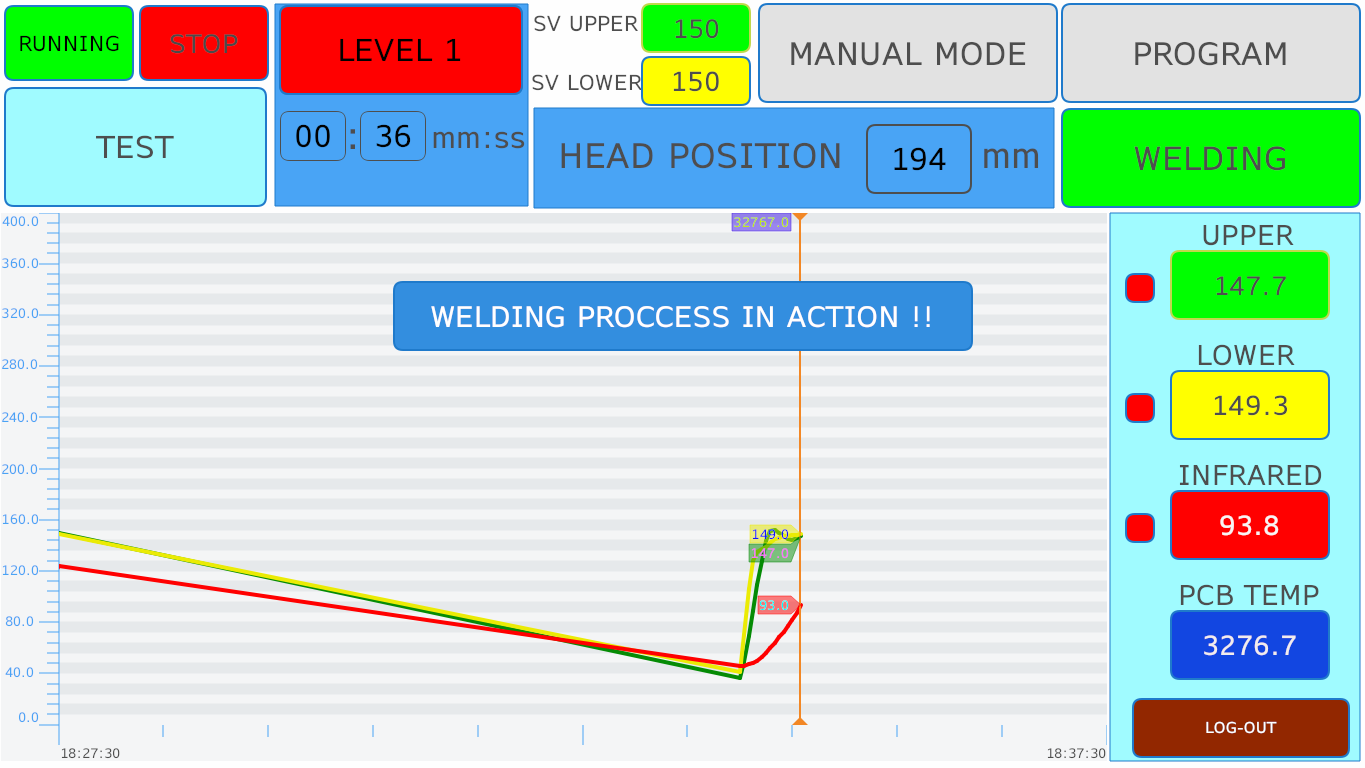

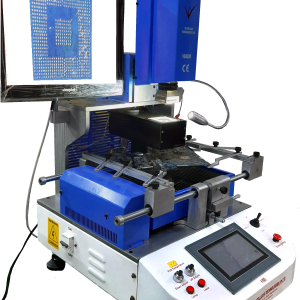

The VD-7200 is a cutting-edge BGA Rework Station equipped with SCADA-based automation, making it a perfect solution for precision rework of BGA, CSP, and other surface-mount components. It incorporates all the features of the VD-6200 but enhances them with automated camera movement, a high-end CPU, and a monitor for superior control and performance.

With its advanced SCADA system, the VD-7200 offers real-time monitoring, control, and data acquisition, allowing users to streamline the rework process. The automated camera module ensures precise and efficient chip alignment, and the high-resolution monitor provides clear visibility for critical operations, making complex tasks easier to handle.

Key Features:

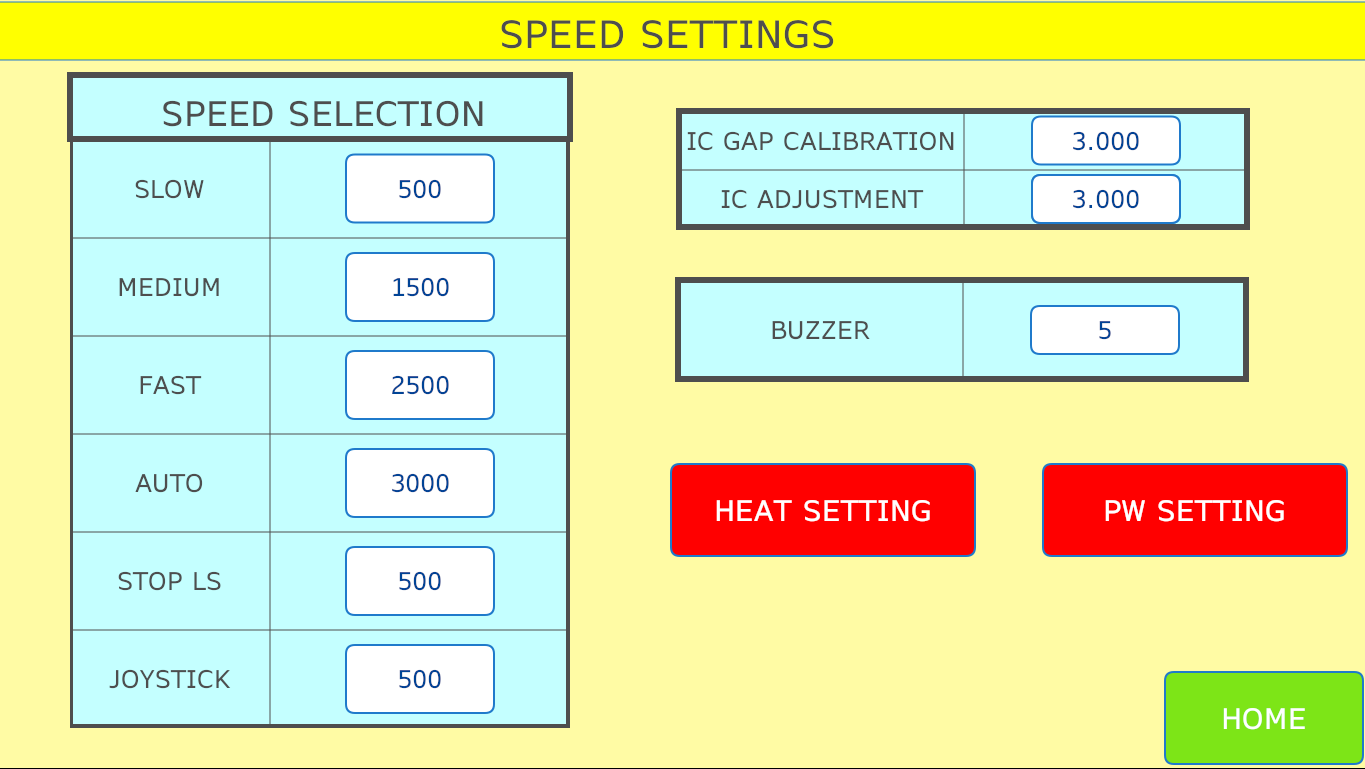

- SCADA-Based Control: Real-time monitoring and control with data acquisition capabilities for superior process management.

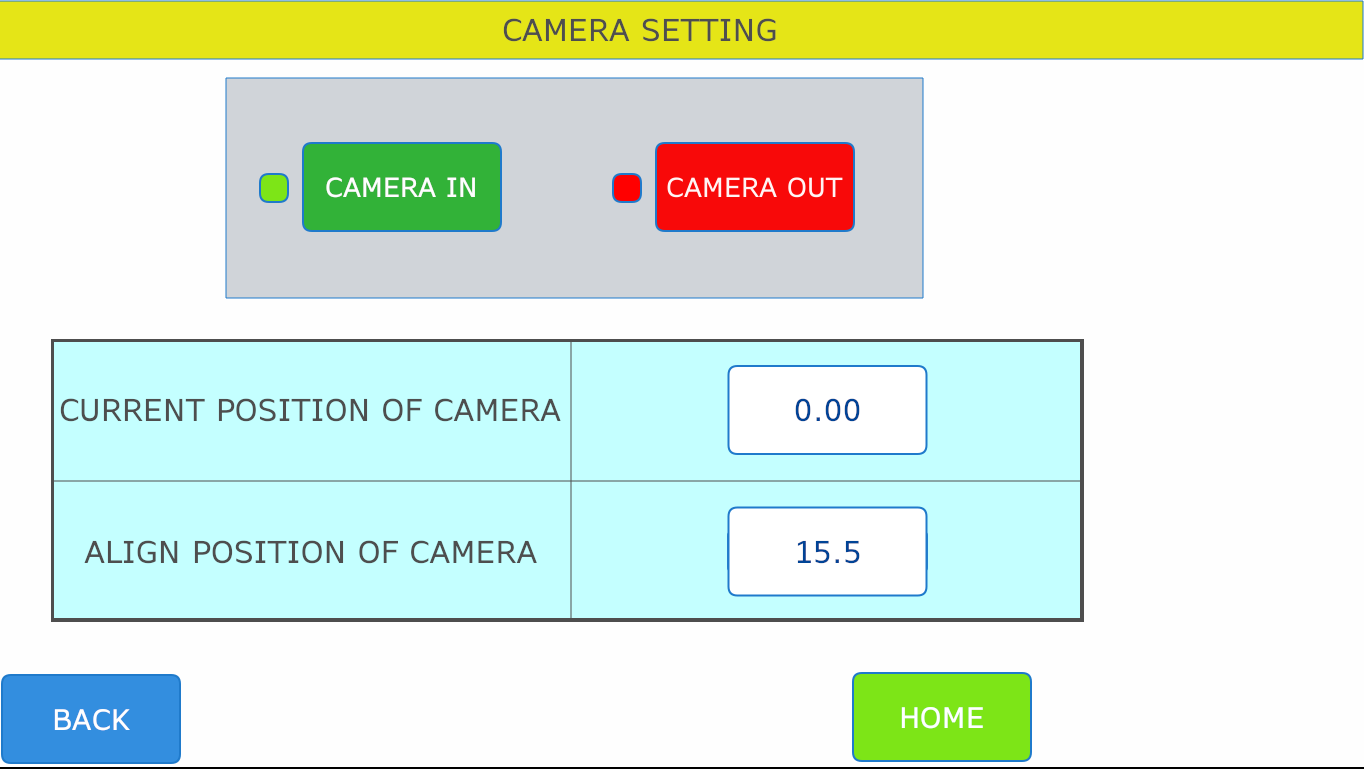

- Automated Camera Movement: Ensures precise and effortless chip alignment during soldering and desoldering operations, reducing the chances of human error.

- High-End CPU and Monitor: Provides faster processing and clear visibility, enabling more efficient rework and monitoring.

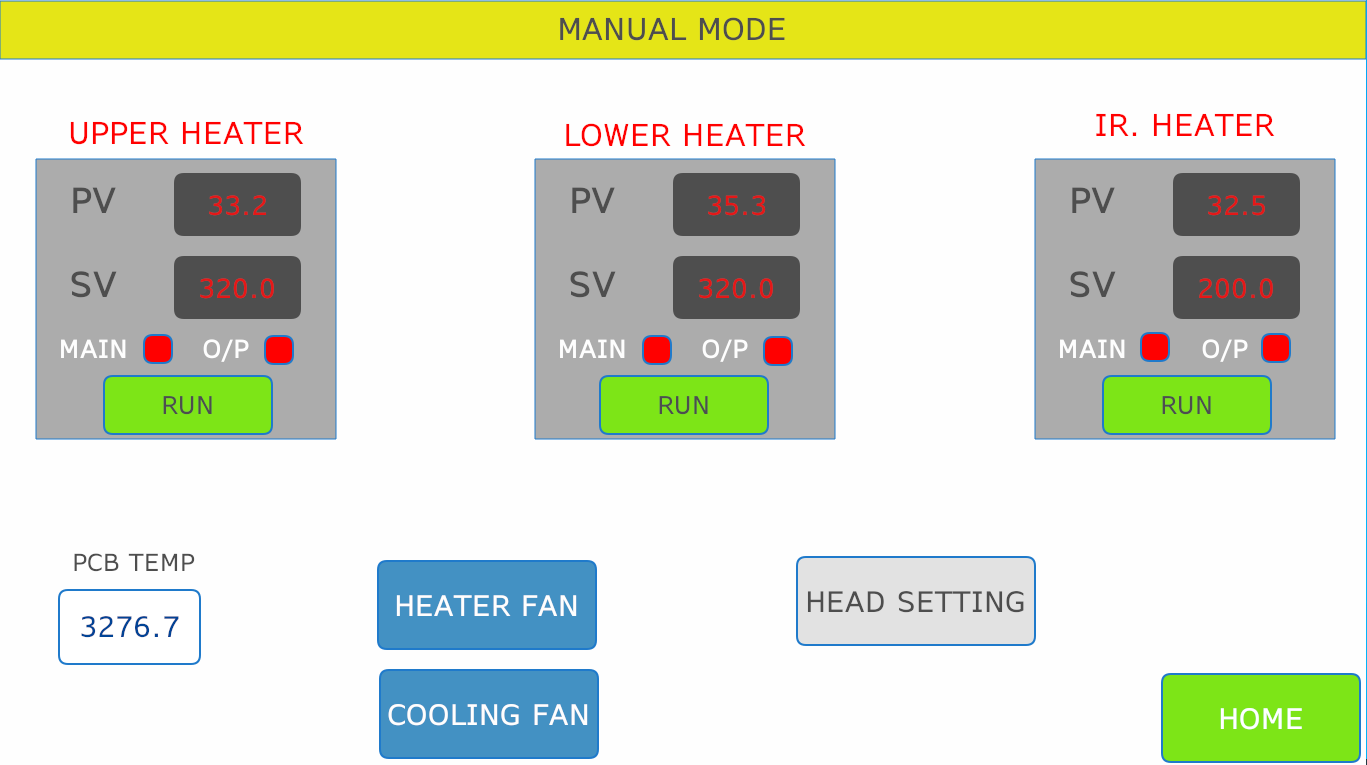

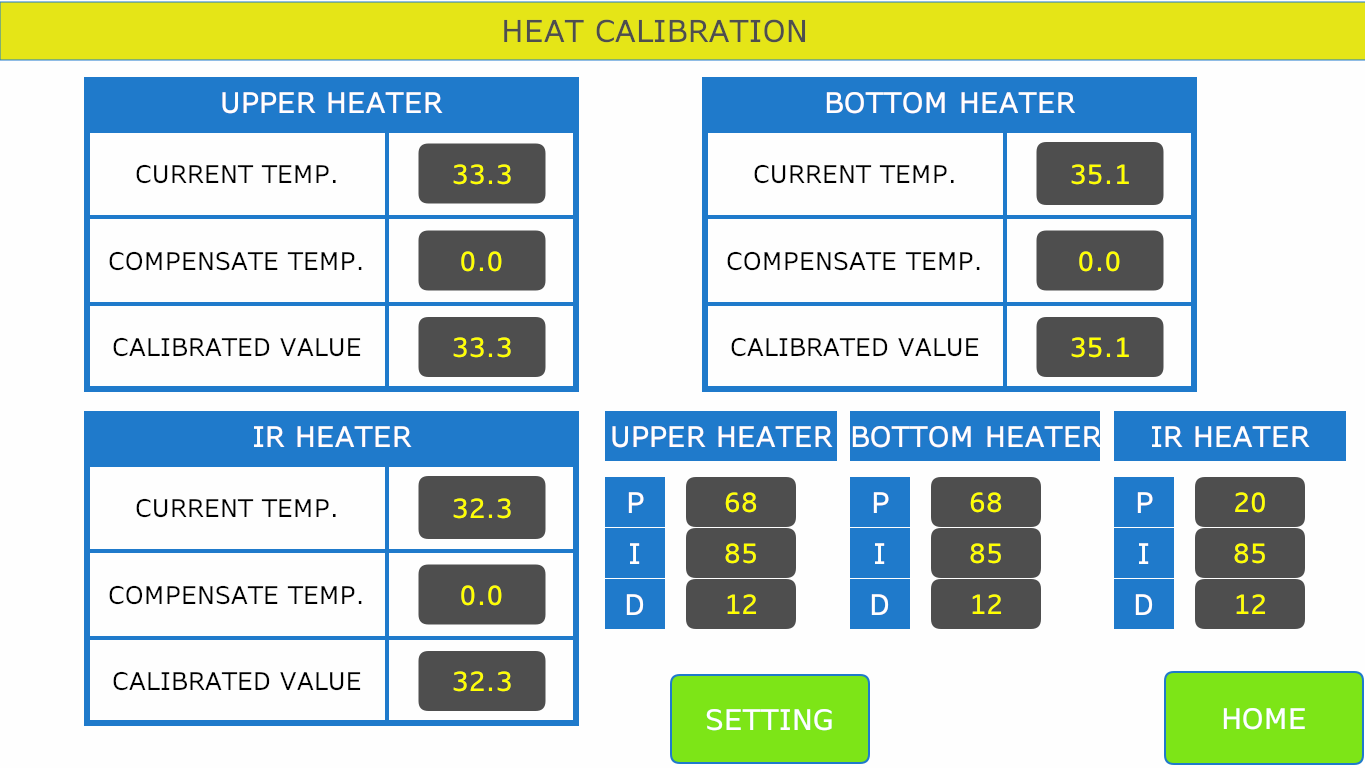

- Multiple Heating Zones: The system includes three independent heating zones (top hot air, bottom hot air, and bottom IR) for accurate and even heat distribution.

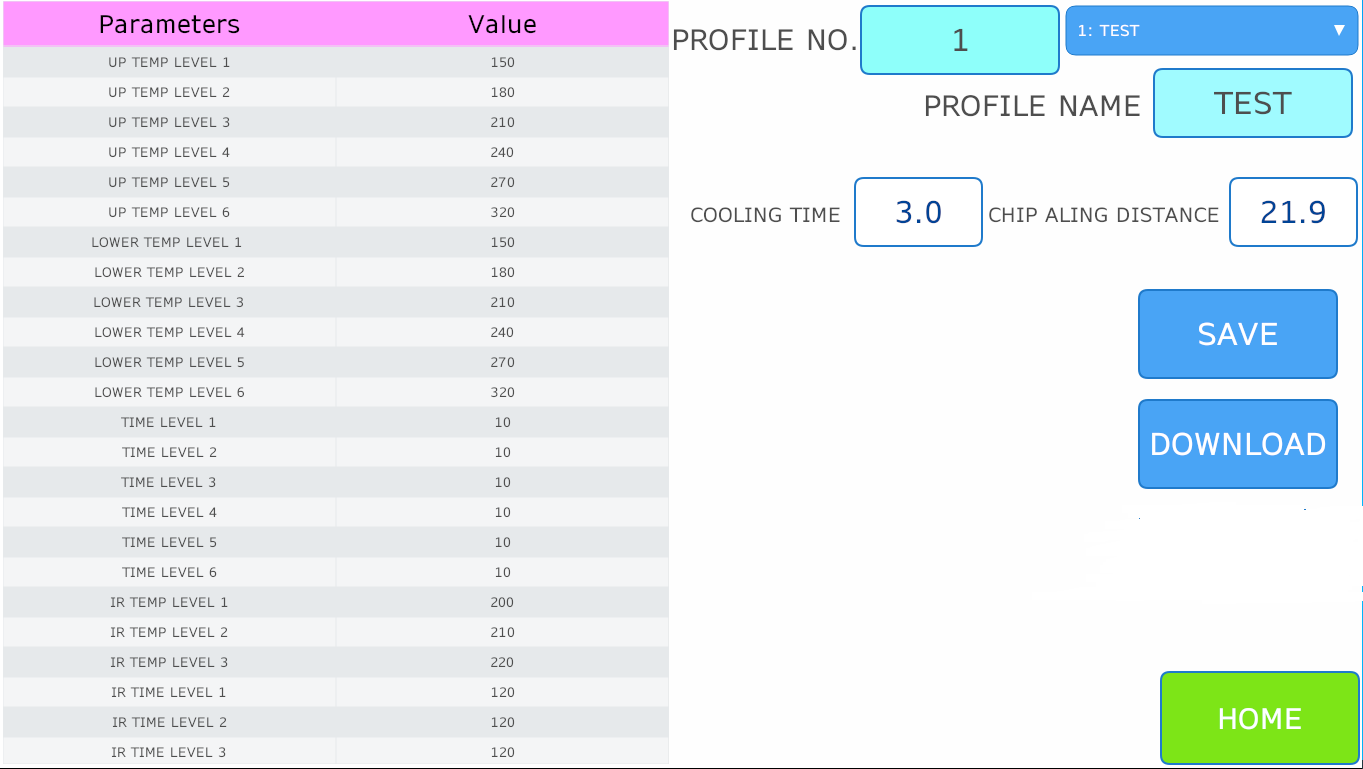

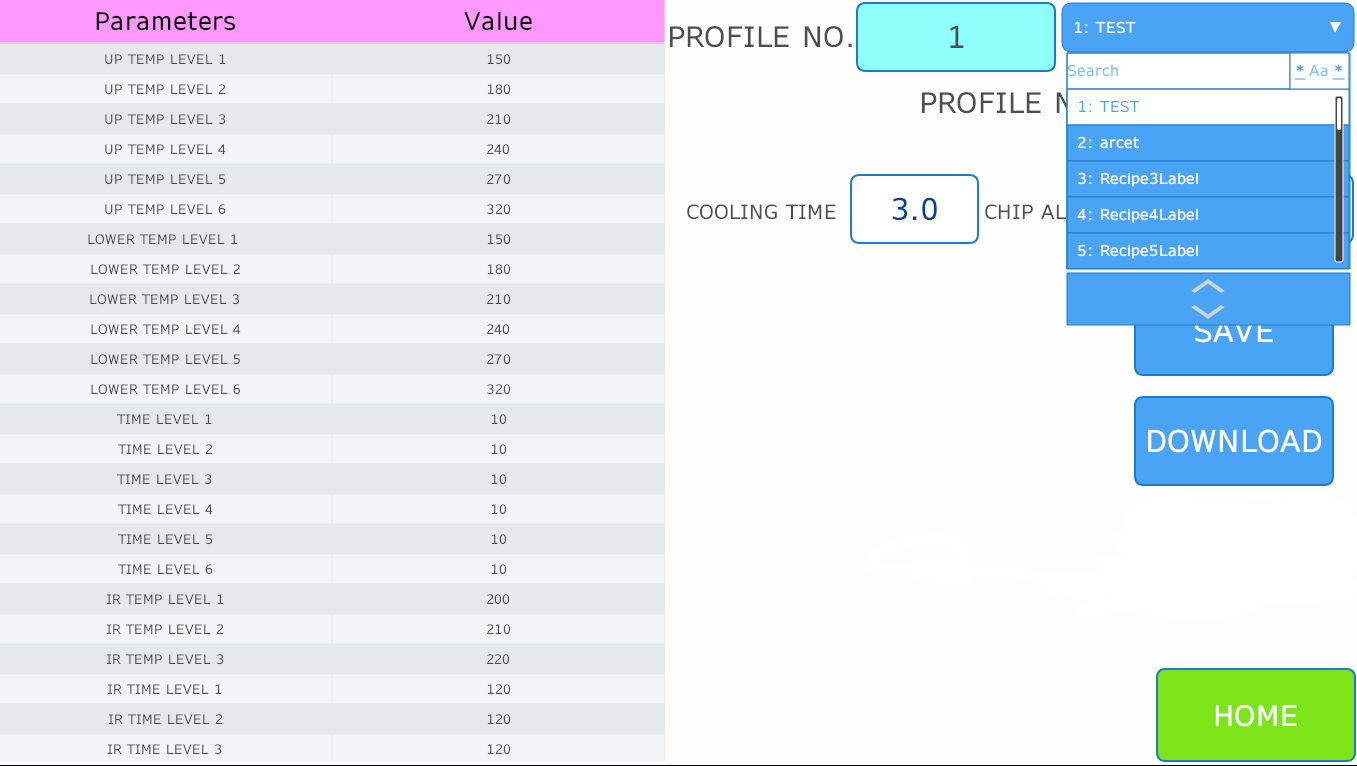

- Built-In Profile Management: Store and recall custom profiles for different components, ensuring consistent results across multiple tasks.

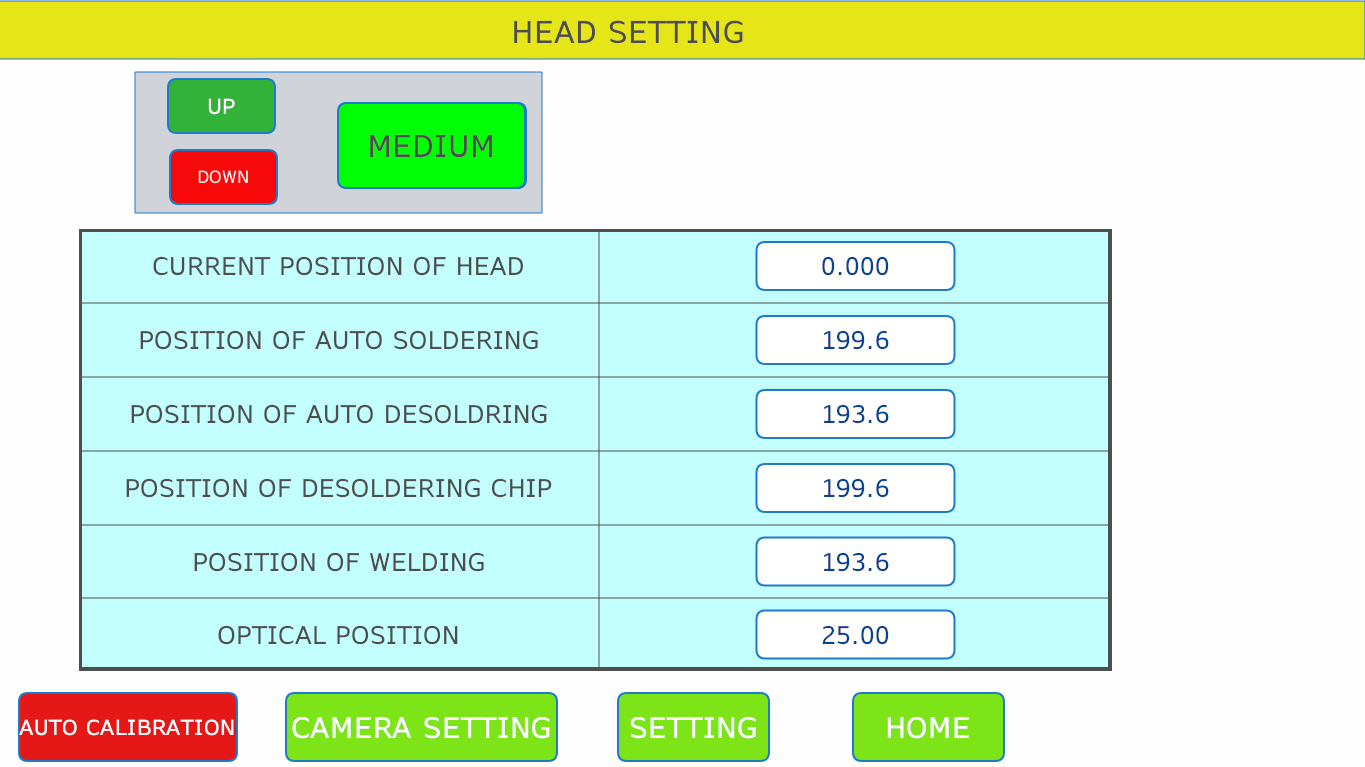

- Touchscreen Interface: User-friendly HMI (Human-Machine Interface) controlled by Mitsubishi PLC for precise operation.

- Precision Positioning: Automated control of the rework head with fine adjustments in X, Y, and Z axes for high-accuracy component placement.

- Safety Features: Integrated safety systems, including temperature control and automated shutdown in case of overheating or system failure.

Specifications:

| Feature | Details |

|---|---|

| Input Voltage | 220V ±10% AC 50/60Hz |

| Total Power | 5300W Max |

| Top Heater Power | 1200W |

| Bottom Heater Power | 1200W |

| Bottom IR Heater Power | 2800W |

| Temperature Control | K-type thermocouple closed-loop with ±3°C precision |

| Camera System | Automated movement for alignment and high-resolution imaging |

| Positioning System | V-groove fixture with automated X, Y, and Z-axis adjustments |

| PCB Size | Max: 450 × 390mm, Min: 65 × 65mm |

| Machine Dimensions | 640 × 630 × 900 mm |

| Weight | 68 kg |

| Monitor and CPU | High-end CPU with large display monitor for SCADA integration |

| Color Options | White, Black, White-Blue |

The VD-7200 is designed for electronics professionals who demand accuracy, efficiency, and full control over their rework processes. Its SCADA-based automation, combined with a powerful CPU and advanced camera system, makes it ideal for industries that require high-quality BGA rework with minimal downtime.

Reviews

There are no reviews yet.